IBC Brand,""RodEnd" & "Camfollower",and "Track Roller"etc

¦General Features¦

Generally, IBC Rod end bearings consist of a spherical inner ring (that called a ball). a housing(that called a body) having a shank or extension with male or female feature and right-handed or left-handed thread and a bush.Spherical inner rings are manufactured from carbon chromium bearing steel which is heated, precision ground, and dichromate treated to minimize friction of contacting surfaces. Housings are made of medium carbon steel and bushes are made from Cu-Zn alloyed brass.

On the other hand. IF30~IF35 and IM30~IM35 are much bigger size than other rod end bearings and specially manufactured considering heavy loads and tilting angle. So, we made these four items steel on steel structure instead of steel on composite material.

IM spherical plains GE20FO-2RS~GE35FO-2RS are inserted with press for heavy duty applications. Exceptionally, the above twelve are regarded as our stadard bearing types and in case of containing bush, they are considered our non-standards.

¦Application¦

Rod ends are mainly used in the construction of control rod linkages, under the status of tensile and compressive loads transmitted throught the control rods. These types are self-aligning bearings designed to take both radial and thrust loads and th have a superior performance especially in rotational and oscillating motions. They are essential components to design machinery and improve their performances in various industrial fields.

¦Bearing types¦

Type IF & IM

Basically, there are two groups: steel-on-composite material rod ends and maintenance-free rod ends. Steel-on-composite material rod ends are appropriate for directional change. We design and manufacture IF and IM with lubricating holes and lubricating nipples which permit relubrication periodically.

Type IFT & IMT

By the way, IFT and IMT are classified into maintenancefree, that is to say self-lubricating rod ends. A PTFE impregnated woven fabric liner ring. These bearings are primarily intended for applications where oscillating motions occur frequently. They boast stable performance and relatively longer life without lubrication.

Type IFTS & IMTS

IFTS and IMTS having same dimensions with IFT and IMT are available by special order. These rod end bearings are made from stainless steel. Do you still lubricate regularly? It's time for using maintenance-free rod ends.

Type IFG & IMG

The rod ends over IF20 and IM20 in dimension are supplied equipped with steel-on-steel spherical plain bearings. So, it is suitable for applications where heavy loads must be required and their service life can be considerably extended by regular relubrication.

SPHERICAL PLAINS

¦General Features¦

IBC spherical plains are kinds of sliding bearings consisting of and inner ring (namely ball) with a sphered outer surface and an outer ring (namely housing) with a sphered inner surface. For GE and SB both inner and outer ring are made of carbon chromium bearing steel which is geated, precision ground and phosphate trated to minimize friction of contacting surfaces. In case of IS and IET, the outer ring is manufactured from medium carbon steel and the inner ring, carbor chromium bearing steel. They are different from how to lubricate each other. For IETS both rings` material is stainless steel. On the whole the spherical surface of the inner ring is polished and finished like a mirror and the outside diameter of the outer ring is minimized so it is easy to insert in even small area.

¦Application¦

Our Spherical plain bearings are particularly suitable for the accommodation of heavy radial loads. They are generally used for axial arrangements in which there is a certain misalignment of the shaft or in which tilting or rotational, oscillatory motions with relatively slow sliding velocities occur. They can also endure a certain amount of thrust load in both axial direcion.

¦Type¦

Type GE

These spherical plains are one kind of sliding bearings with function of self-aligning for heavy loads and they are made of carbon chromium bearing steel which is heated, ground and phosphated. This type can endure radial heavy loads, certain thrust loads from both axial directions and even impact loads so they are installed in the end of hydraulic cylinder for various kinds of construction equipment or suspension for trucks. After all, it is for low speeds, heavy loads and oscillating motions. It is widely adopted in Europe. Especially, GE..2RS has dust seals at both sides to prevent contamination. Generally lubrications is needed regularly and lithium-base grease with molybdenum is recommended.

Type SB

These spherical plains are self-aligning and sliding bearings for heavy loads which are hardened, ground and then phosphated. It is made out of carbon chromium bearing steel, too. SB is wider and thicker than GE and is suitable for more heavy loads than GE. In general, periodic or continuous lubrication is required and lithium base grease with molybdenum is recommended.

Type IS

The outer ring is carbon steel but not hardened, so you should be cautious not to damage it when you assemble. There is minimum 20/1,000mm of clearance between the inner ring and the outer ring. Be sure that the inner ring rotate freely after make up. Improper assembling may cause bad operating conditions. The surface of the inner ring is polished and finished like a mirror and copper alloy is inserted in the sliding contact surface of the outer ring. The copper alloy has a good wear resistance. IS is also one of the sliding bearings with accommodating misalignment.

Type IET

The outer ring of this spherical plain is also made of carbon steel and is not hardened, so you have to pay attention when you fit it in order to avoid the damage of the outer ring. In accordance with international standard, we designs this type IET which can be used in a small area. A PTFE liner is overlaid on the contact surface of the outer ring. This enables the bearing to work without lubrication because of it's excellent sliding and wear resistance property. In many cases, they can operate without maintenance, nobeullije Non oil contained material.

Type IETS

It is made of stainless steel to prevent corrosion and a PTFE liner is overlaid on the contact surface of the outer ring. It is suitable for the chemical applications and under water equipment.

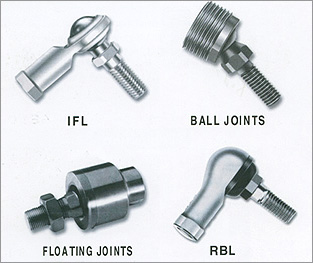

BALL JOINTS

¦Type¦

Type RBL

RBL are kinds of bearings for linkage control, which are rotating and oscillating to make it easy for rod linkage motion in various industrial machinery. Stud bolts and high precise steel balls are welded together electrically. Rubber caps are used to keep waterproof and rustproof and to contain grease for self lubrication. The material of the RBL body is Zn-alloy and the body is molded by die-casting. In comparison with the conventional rod ends connected with pins, this RBL has a simple structure and a wide variety of industrial applications.

FLOATING JOINTS

These are such types stud bolts welded electrically with high precise steel balls are assembled to the steel body. They are used for linear motions to absorb the moment resulted from eccentricity and unparallelness when rigged at the end of hydraulic and pneumatic cylinders. They also guarantee an extended long life of hydraulic and pneumatic cylinders.

STUD TYPE TRACK ROLLERS

¦General features¦

There are two types of track rollers or cam followers IBC manufactures. One thing is stud type track roller bearings. Another is Yoke type track rollers. IBC Stud type track roller bearings consist of a stud serving as a shaft, a roller and needies which are placed between the roller and head of the stud. The flange-shaped head of the stud and the thrust washer guide the needles to work well and keep the outer ring toward axial direction. These two types are all non-separable types. Most elements such as shafts, rollers, needles and thrust washers are made of carbon chromium bearing steel.

¦Application¦

These are proper for static loads and heavy loads at low and middle high speed. In the view of it`s function, there are various usages in accordance with those kinds of rollers such as guide rollers, rocker valve rollers, cam rollers for slide and pressure rollers. IMC stud type track rollers are suitable for many kinds of machines like automatic machinery, specialized machinery, cam-working assembly, various carrying facilities, conveyors or the tool exchanger for machining center.

¦Type¦

Type CF & CR

CF and CR are the main standards of stud type track rollers we manufacture. Type CF is based on metric dimension and type CR on inch dimension. These two types are in common use. These features and applications are in next few page. Details including mounting or lubrication are found in this chapter.

Type CF..M & CR..M

CF..M, CR..M having the same dimensions as CF and CR are available by special order. These CF..M and CR..M types are made from stainless steel.

Type CFO

CFO is one of our non-standard stud type track rollers. This type also has the same elements and working range that CF and CR have. However this makes a difference with respect to application. CFO has a thread for piping at the end of stud, so they can take the grease supply from the central lubrication system. The most of CFO type are applied to this purpose.

Type CFE

CFE Type is more easy to adjust the radial position turning the shank of stud equipped eccentric ring which has eccentricity around 0.5~1.5mm, so that by turning the stud it could be simply adjusted in the center position of the axis of the stud. The eccentric ring compensates for the lack of precision and will give you conveniences about backlash adjustment, level adjustment when we install several pieces together and matching with cam slot.For turning the stud, a hexagonal wrench is generally more convenient that a screwdriver, therefore we supply stud type track rollers with a hexagonal wrench socket in the head of the stud. To provide a means of easy axial adjustment for precise positioning of track rollers, type CFH is a more advanced and convenient type compared with the previous type CFE with an eccentric ring.

Type CFH

CFE TYPE is easily to adjust the radial position turning the shank of stud equipped eccentric ring which has eccentricity around 0.4~1.5mm, so that by turning the stud it could be simply adjusted in the center position of the axis of the stud. The eccentric ring compensates for the lack of precision and will give you conveniences about backlash adjustment, level adjustment when we install several pieces together and matching with cam slot. For turning the stud, a hexagonal wrench is generally more convenient than a screwdriver, therefore we supply stud type track rollers with a hexagonal wrench socket in the head of the stud.

Type NUKR

IMC stud type track rollers of series NUKR start with an outside diameter of 35mm and end with an outside diameter of 90mm. They are equipped with two rows of needle rollers without cage. These are suitable for high loads. NUKR..R which feature crowned outer ring are available. NUKR..SL with cylindrical outer ring are required to make by a special order.

Type KR

KR type is non-standard item which is produced by our own super precision manufacturing process. It is applied to the ATC(Automatic Tool Changer) of Machining Center and is supplied by the customer`s specification.

YOKE TYPE TRACK ROLLERS

¦General features¦

York type track roller bearings we produce and supply are NART, NUTR, NAST.IBC Yoke type track rollers consist of and inner ring, an outer ring, two retaining washers and a caged or a full complement needls rollers. In case of NUTR, there are additionally two snap rings and it has only a full complement needls rollers, not a caged needle rollers. Most of the elements including both rongs, washers and needles are manufactured from carbon chromium bearing steel. The types with seals are very appropriate for providing not only a good retention of lubricant but protection from foreign material. Grease is provided through a lubrication hole in the inner ring.

¦Applaction¦

IBC Yoke type track rollers are suitable for the accommodation of high loads. They are applied as guide rollers, rocker valve rollers, eccentric rollers, table support rollers. They also can be used for many other applications involving either linear movement or the translation of rotaty motion to axial motion and they are also readily available, easily mounted and low-price bearings.

¦Type¦

Type NART

There are two kinds in a series of NART which is a non-separable type, one has a retainer (or cage) to make needles rotate freely at high speed and the other is just stuffed with needles so as to endure heavy loads at relatively low speed. The range of bore diameter is from 5mm to 50mm and NART..R which has crowned outer ring is our regular products. The interval of lubrication is subject to operating conditions and it is normally from six months to two years for caged one can every six months for full complement of needle roller. You may lubricate through a lubricating hole with Albania type grease which has good performance at high temperature. When you assemble NART to the housing you should position the lubricating hole on the other side of a load direction.

Type NUTR

Yoke type track rollers of series NUTR are one kind of NART in which only needles are stuffed without retainer. The bore diameter and outside diameter of this series start with 15mm and 35mm respectively. There are two types of NUTR which have the different outside diameter even though it has the same bore diameter, for example NUTR15-35, NUTR15-42. Moreover, NUTR..R has crowned outer ring, but NUTR..SL has cylindrical outer ring. NUTR series a dopt double row of needle roller to withstand high loads and well designed to withstand repeated impact loads. There are steel ring labyrinths which make it to be a non-separable type by connecting the outer ring and the retaining washers. The steel ring labyrinths also have the effect to be sealed to prevent contamination. Working temperature doesn't matter with the steel ring labyrinths because they are not in contact with working areas. When you assemble this, position the lubricating hole on the other side of a load direction in order to avoid load concentration.

Type NAST

Yoke type track rollers of series NAST are newly developed to satisfy our customer's increasing requirements. This type is one of our standards and consists of an inner and an outer ring, retaining washer and a precision cage. This NAST... characterizes not to have a thrust washers fixed with inner ring. NAST..ZZ which has two retaining washers on both sides is a little different from NART. The thrust washers of series NART are pressed into the inner ring, thus making the rollers unseparable. in series NAST, the retaining washers are loose and the rollers are separable. NAST are all separable types.

RodEnd/Camfollower/Track Roller_etc

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share RodEnd/Camfollower/Track Roller_etc in Social Media