Diamond

Cutting Tool (Tungsten carbide, Cernet, Ceramic)

Electric Parts (Ceramics(Mullite, Steatite etc.), Silicon, Germanium)

Magnetic Materials (Ferrite, Rare earth-fortified cobalt)

Hard and Brittle Materials (Glass/Quarts/Ceramics)

Stones, Ceramic Products etc (Stones/Reflector/Tiles/Asbestos /Asphalt/Concrete)

Wear-resistant Metals (Sprayed metals/Stellite/Ferrotic)

Plastics

Graphite

CBN

Cutting Tool (SKH/SKS/SK)

Wear-resistant Tools (SKD/Stellite, Sprayed metals(meterco, etc)

Structural Elements (SCM/SNCM/SCr/SUJ)

Corrosion-resistant metals (SUS)

Heat Resistant Metals (SUH/Inconel/Ti alloy/Nimonic /Waspalloy/Hastelloy/Udimet /Magnetic materials/Sendust/Alnico)

Cast-iron

Magnetic Materials

1. Peripheral Speed

The life of the wheel, stock removal rate, and surface roughness highly depends on peripheral speed. The operator should therefore choose the optimum peripheral speed. As Soon Yang Vitrified Diamond wheels are the wet type, the recommended peripheral speed is 1500-2500m/minute, depending on the ground material(EX. 1030-1300 for PCD).2. Infeed

Infeed is one of many important factors to determine grinding efficiency. Excessive infeed can result in shorter life span of the wheel. The optimum depth of the cut is under 1/3 of the mesh size.

Grit size Diamond Grinding Wheel

#100-#200

#140-#200

#230 or finer

Depth of Cut

0.00-0.03mm

0.01-0.02mm

0.01mm or less

3. Macine with enough Power

The super vitrified diamond wheels are designed to be used with water for both lubricatin and cooling rather than a mineral oil based fluid. By running the miscible oil type cutting fluid of between 3 and 5% by volume on the wheel, the efficiency of the wheel can be significantly improved. The use of water and the lubricant minimize the problems of waste disposal and the need to comply with a local environmental legislation.4. Truing and Dressing

Generally, truing is necessary when trembling is found and is followed by dressing to get a good stock removal rate. However, the Soon Yang Vitrified Diamond grinding wheel, truing is almost unnecessary, since the high pore rate itself keeps the wheel loading effect very low and reduces occurrence of heat during grinding procedure.5. GC Stone Mesh for Truing

It is recommended to use two coarser sizes than the diamond particle size to finish truing within a short time.6. Size GC Stone for Dressing

It is recommended to use a mesh that is two steps finer than the diamond mesh to protrude diamond particle in the wheels.7. Surface Finish

Two separate cyles are recommended in order to achieve a high rate of stock removal and a good surface finish. The fine mesh should be used after the rough mesh.

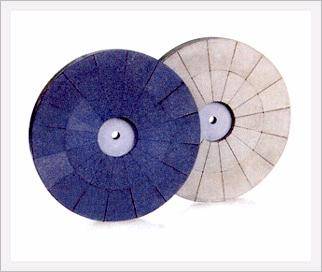

Vitrified Diamond and CBN Grinding Wheel

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Vitrified Diamond and CBN Grinding Wheel in Social Media