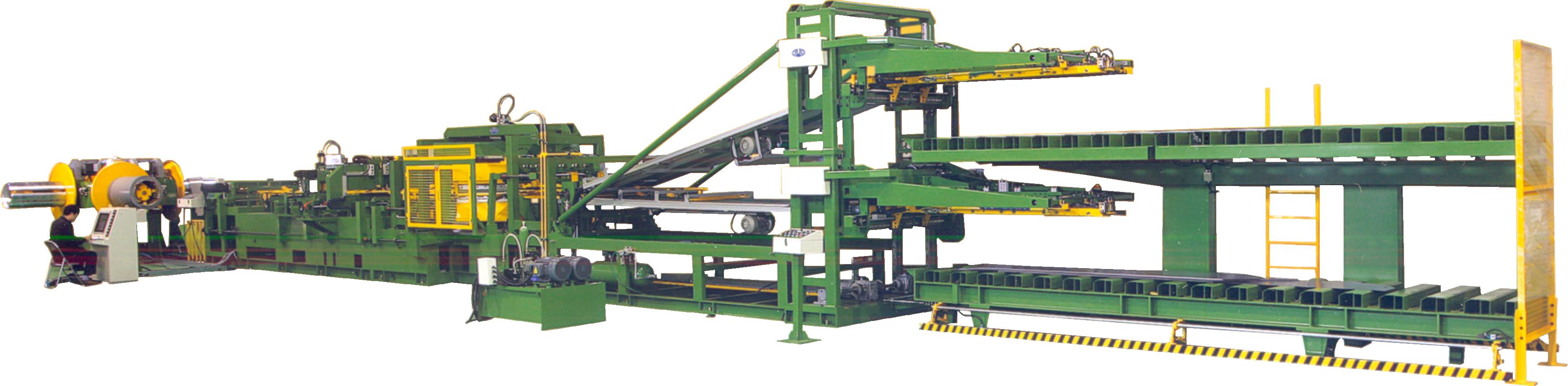

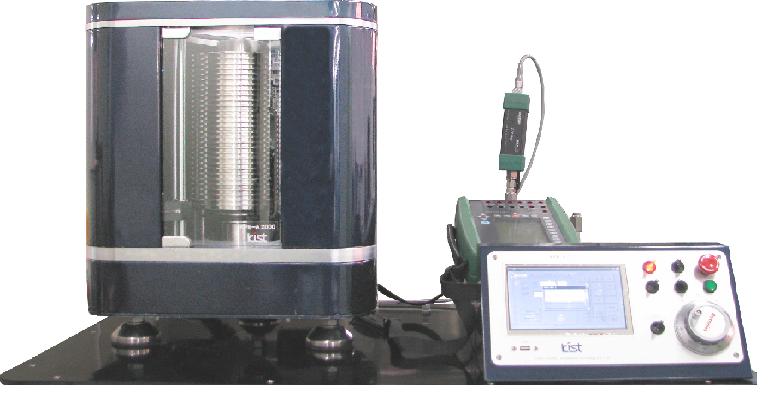

WAW series (Dual space) Servo-hydraulic Universal Testing Machine is ideal for high-capacity tension, compression, bend/flex, and shear testing. It accords with the relative requirements of BS, EN, ISO, ASTM, JIS, GB, NF and many other testing methods. These frames feature dual spaces so users can quickly change between tension and compression testing without having to remove heavy fixtures.

HUALONG WAW has long been recognized as the standard for accuracy, dependability and versatility in servo-hydraulic universal testing machines.

Extra-length screws and columns, with an adjustable lower crosshead, to increase the available test space for longer test specimens.

Semi-open front hydraulic wedge clamps for easier loading and allowing rapid loading and unloading of specimens.

Rigid in 4-column load frame construction providing superior axial and lateral stiffness and minimum maintenance, low reaction at specimen failure.

lower crosshead movable to increase distance between grips

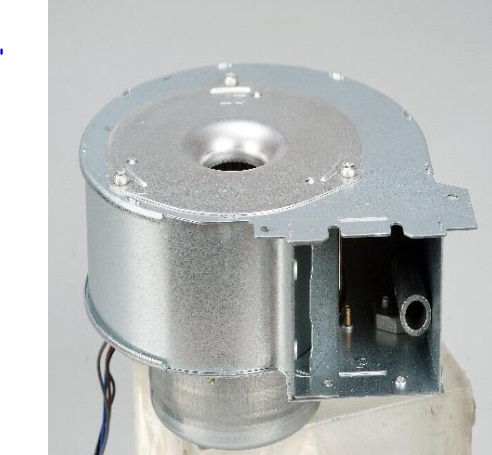

Servo valve attached direct on actuator providing close-coupled servo valve and accumulators for improved performance and reduced pressure fluctuations

With digital displacement transducer for the best positioning and measuring accuracy

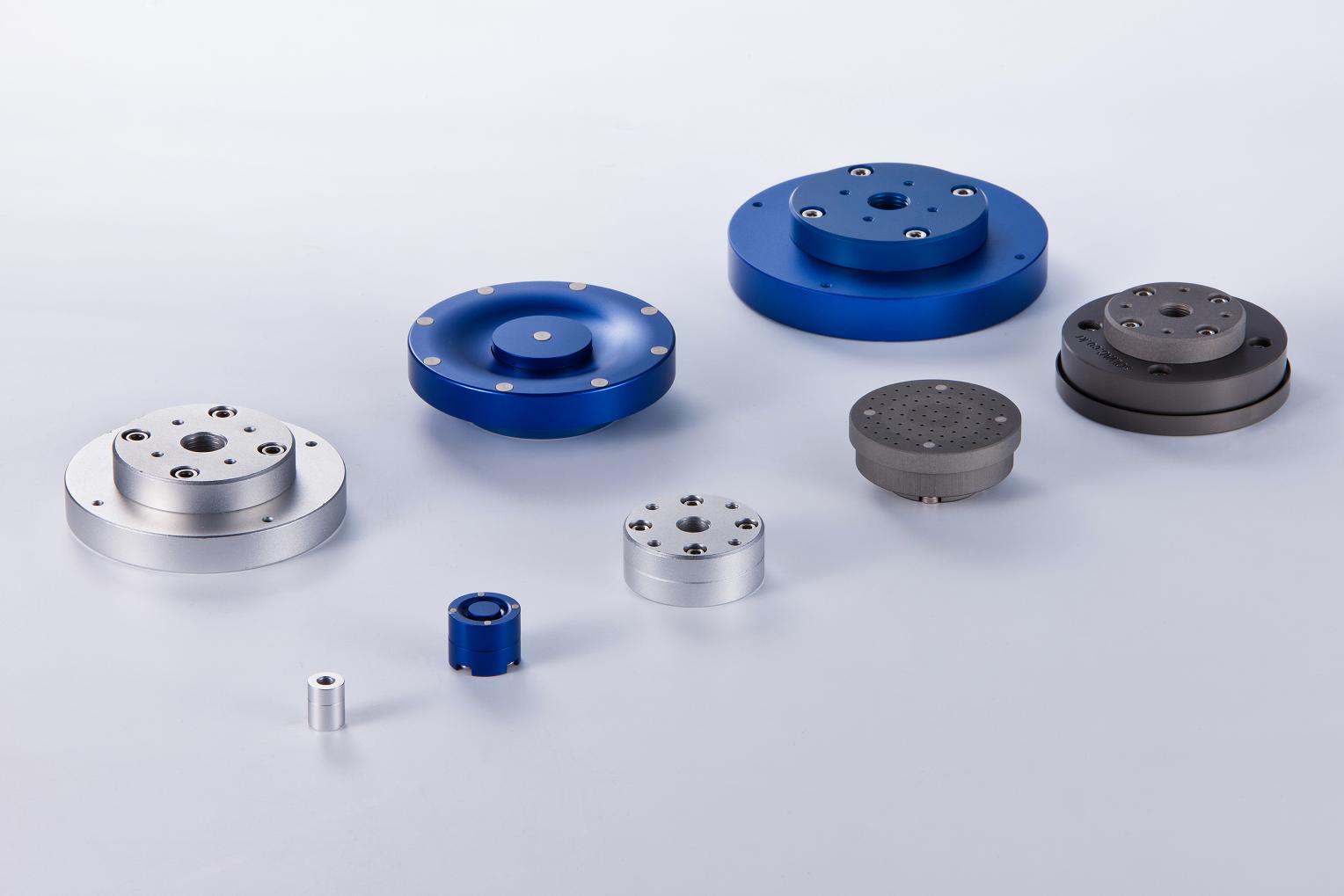

Hydraulic operated wedge grips available

Including grip control system mounted direct at the machine

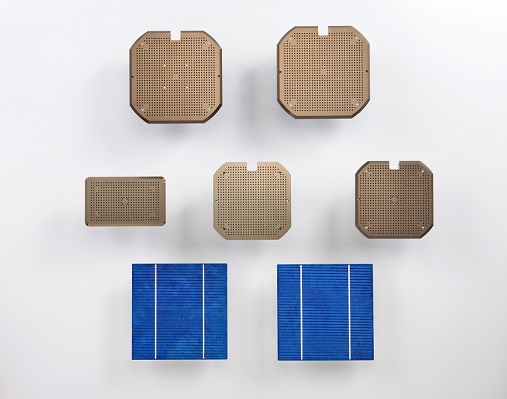

Tooling for tension, compression, bend/flex, shear, and other tests.

With chrome plated columns for easy cleaning and longest life.

Application range

metals-(wire, rod, tube, strip, plate, strip),

fasteners (tensile, proof, single and double shear),

construction materials (reinforcement bar, wire, mesh, folding, compression of concrete) and components)

EN10002-1, ISO 6892, ASTM E8, ASTM C39,/EN12390-3, UNI6556/ASTMC469/DIN1048/ISO6784

ASTM A 370/A416, ISO 15630

ISO 7438, GB/T 232, ASTM E190, AWS B4.0, API 5L

ASTM F606, SAE J429, NASM 1312, ISO 898-1 CE Compliant

Technical Specifications

Model

WAW Series

50

100

200/300

500/600

1000

1500

2000

Capacity

kN

50

100

200/300

500/600

1000

1500

2000

Load resolution

kN

Capacity/300, 000 (fully auto scaling of single measurement range)

Machine specifications

Stroke

in

5.9

9.8

mm

150

250

Testing speeds

in/min

0.04-13

0.04-7.9

0.04-5.9

mm/min

0.1~330

0.1~200

0.1~150

Adjustable crosshead speed

in/min

17.7

13.8

12.6

mm/min

450

350

320

Load frame

dimensions

Clearance between grips

in

23.6

25.6

27.6

29.5

31.5

mm

600

650

700

750

800

in

49.2

mm

1250

Clearance between platens

in

19.7

21.7

22.8

23.6

mm

500

550

580

600

in

33.5

mm

850

Clearance between columns

in

16.9

21.3

22

26.8

mm

430

540

560

680

Nominal maximum specimen sizes

Diameter

in

F0.866

F1.26

F1.574

F2.362

F2.756

mm

F6~F14

F14~F22

F6~F16

F16~F32

F13~F27

F27~F40

F20~F40

F40~F60

F20~F50

F50~F70

Thickness

in

0.591

1.181

1.575

1.575

1.969

mm

15

30

40

40

50

Width

in

2.362

2.953

3.543

4.331

5.906

mm

60

75

90

110

150

Platen dimensions

in

F4.331

F16.535

F6.890

8.661*8.661

mm

F110

F120

F175

220*200

Machine dimensions

Load frame

in

22.8*17.7*76.8

29.5*22*80

33*24*83

35*25*92

48*25*92.3

mm

580*450*1950

750*550*2035

850*600*2115

890*640*2345

1220*640*2345

Control console

in

45.3*31*35.4

mm

1150*780*900

Weight

lbs

5, 732

6, 173

6, 393

7, 165

8, 995

kg

2, 600

2, 800

2, 900

3, 250

4, 080

General Specifications

Load Measurement Accuracy:

±0.5% of reading to 1/100 of load weighing system capacity meets or exceeds the requirements of the following standards: ISO 7500-1, EN 10002-2, ASTM E4, JIS B7721.

Strain Measurement Accuracy:

±0.5% of reading to 1/50 of full scale with most ASTM E83 class B or ISO 9513 class 0.5 extensometers meets or exceeds ASTM E83, ISO 9513, and EN 10002-4.

Speed Accuracy:

Set speed

Servohydraulic universal testing machine

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

.jpg)

Share Servohydraulic universal testing machine in Social Media