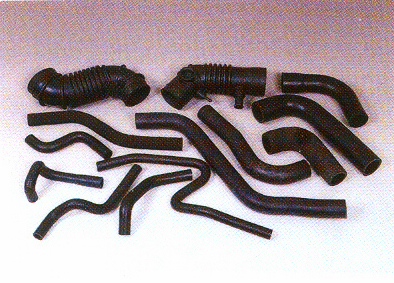

Description of Liquid Silicone for Injection Molding:Liquid Silicone for Injection Molding is a two-component liquid silicone rubber for injection molding processes. The silicone rubber shows a higher productivity, high transparence, less yellowing and low volatile contents. It would be possible to increase productivity by reduce injection time and total cycle time. Also, it is easier to inject into the cavity of the mold which is more complicated designed. In addition, higher transparency and less volatile content make it most suitable for consumer products.Applications of Liquid Silicone for Injection Molding:Because of the outstanding properties, The liquid silicone rubber for injection molding is particularly suitable for the following elastomeric articles: baby nipples, medical tubs, cake molds, food molds, sealing elements, O-rings, stoppers, diaphragms, keypads, bellows, vibration dampers, air vent flaps, switch covers, pressure cookers parts, cable connectors s.o.Specification of Liquid Silicone for Injection Molding:Vulcanisates consisting of liquid silicone rubber are distinguished by the following properties:High productivity, high transparenceHigh flowability, low viscosity and short injection time.Low volatiles content; Fast cureExcellent mold release, Excellent Thermal stabilityExcellent compression set; Excellent resilienceHigh stability to ozone and ultraviolet lightOutstanding resistance to ageingNot readily combustible, does not melt or dripEasy-pigmentable with LSR Colour Pastes fulfill the requirement of KTWProcessing Recommendations of Liquid Silicone for Injection MoldingReady-to-use mixtures (of the components A and B) are fed directly to the injection molding machine from the original containers by means of a metering and mixing unit. The mixture, consisting of the two components in the ratio 1:1, is injected into the heated mould. Because of low viscosity, the injection daospeed and injection pressure need to be carefully adjusted so that the injection time can be decreased. At mould temperatures of 170 - 230°C, the addition -crosslinking silicone rubber vulcanises free of dissociation products within a few seconds. Excellent flowability and easy demoulding permit fully automated production of large numbers of articles in shorter total cycle times.SHELF LIFE of Liquid Silicone for Injection Molding: Correctly stored in its original unopened container at room temperature (24°C). The liquid silicone rubber has a shelf life of 6-8 months from the date of manufacturing. Containers, which have been opened, must be kept tightly closed afterwardsPACKAGE of Liquid Silicone for Injection Molding: 20kg/drum part A + 20kg/drum part B and 200kg/drum part A + 200kg/drum part B.

Liquid Silicone for Injection Molding

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Liquid Silicone for Injection Molding in Social Media