Ceramsite sand/Ceramic foundry sand/Cerabeads

|

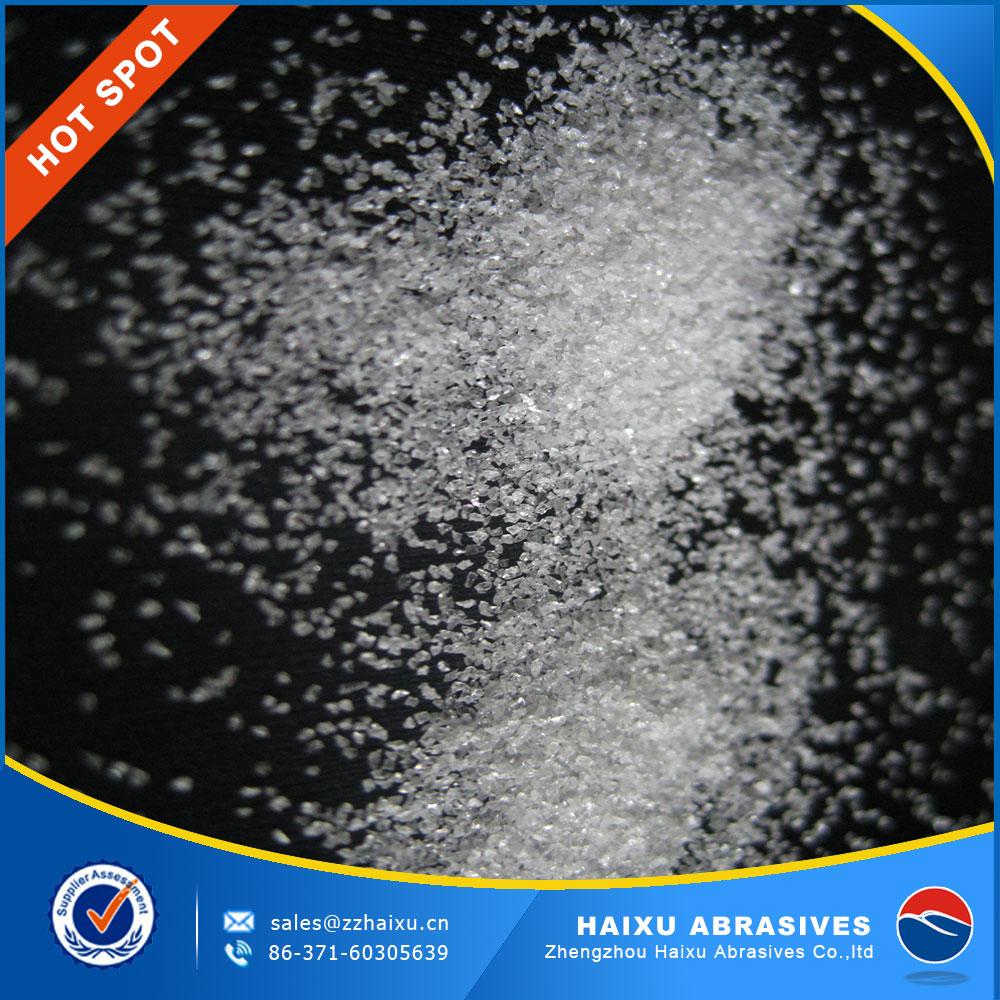

This new developed specific Foundry Sand is produced from the special selected high quality refractory raw material at very high temperature at 2,300 – 2,500℃. Our these ACFS sand has excellent solid cores with high strength and very low resin addition rates. The materials has excellent crystalline with formula is 5Al2O3-SiO2. Application: Shell moulds and cores for casting gray, Malleable and nodular cast iron, alloyed steel and carbon steel, non-ferrous metals, etc. |

|

The Main Advantage Stabe quality on the chemical composition Perfect grain round shape and various grain sizes High gas permeability High temperature resistance Good break down and fast curing and good release

|

Chemical Composition

|

SiO2 |

5– 15% |

|

Al2O3 |

70–85% |

|

Fe2O3 |

5%max |

|

TiO2 |

5%max |

|

MgO |

0.5%max |

|

K2O |

0.5%max |

|

CaO |

0.5%max |

Physical Character

|

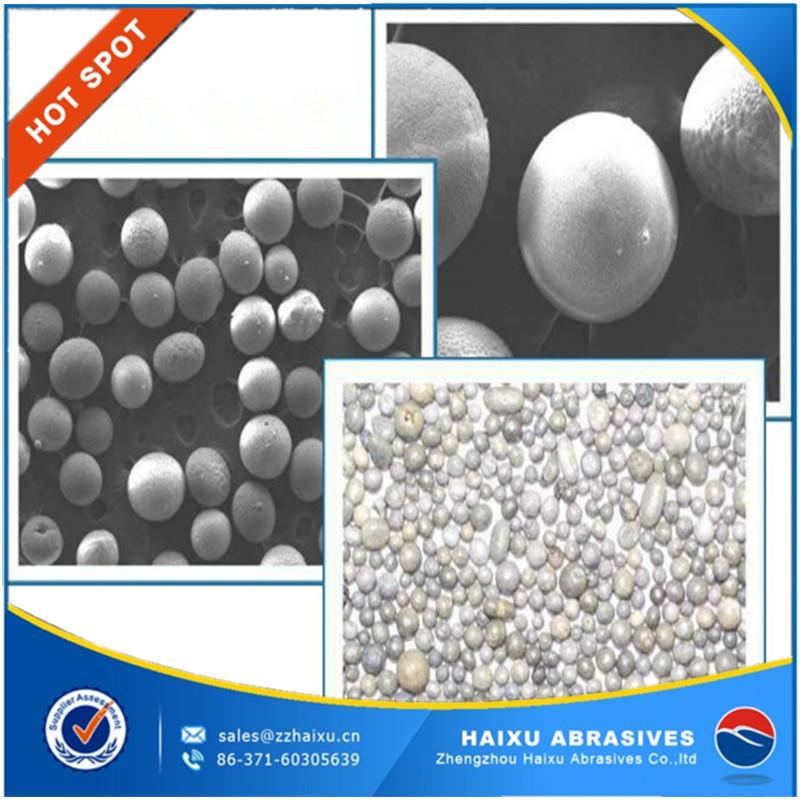

Grain shape |

Perfect round ball shape |

|

Color |

Brown-Black |

|

Angle index |

1 .1 max |

|

Size rang |

0.053-3.36mm |

|

Loose Bulk Density |

1.9 – 2.1 g/cm3 |

|

Refractoriness |

2050℃ |

|

Liner thermal expansion |

(200℃ - 1000℃) 5×10-6/℃ |

Main Advantage

|

1 |

Stabe quality on the chemical composition |

|

2 |

Perfect grain round shape and various grain sizes |

|

3 |

High gas permeability |

|

4 |

High temperature resistance |

|

5 |

Good break down and fast curing and good release |

|

6 |

Perfectly round shape with higher fluidity improves fill-in efficiency while reducing the resin level |

|

7 |

Smooth surface of spherical shape greatly improves collapsibility after pouring |

|

8 |

Very low thermal expansion ensures fewer or no casting defects such as veining and deformation |

|

9 |

Excellent thermal conductivity and heat absorption capacity close to that of Zircon |

|

10 |

Superior refractory equivalent to Zircon and Chromites |

Applications

|

1 |

Widely used in foundry technique like resin-bonded sand, sodium silicate sand, and clay- bonded sand for sand core and casting mould making |

|

2 |

Replace chromite sand and widely used in sand core making like jacket core, oil duct core, tappet core of engine. |

|

3 |

Replace chromite sand for steel casting facing sand and sub-layer of molding sand (backing sand). |

|

4 |

Widely used as dry sand and sand box for EPC process and V method of casting processes. |

|

5 |

Widely used as the main raw materials of advanced refractory products (Ladle drainage sand,gravity casting material, casting coating, etc.). |

|

6 |

Widely used as cleaning sand for copper and aluminum alloy castings. |

PS:The main performance comparison of ceramic foundry sand,Chromite sand and Zircon Sand

|

|

Ceramic Foundry Sand |

Zircon Sand |

Chromite Sand |

|

PH Value |

7.65 |

4.56 |

8.24 |

|

Bulk Density(g/cm) |

1.95-2.05 |

2.9-3.1 |

2.6-2.7 |

|

True Density(g/cm) |

3.4 |

4.4-4.71 |

3.9-4.8 |

|

Shape |

spherical |

Irregular |

Irregular |

|

Binder into water(Waterglass +CO2 Hardness) |

3-4% |

7-8% |

7-8% |

Share Ceramsite sand/Ceramic foundry sand/Cerabeads in Social Media