Sewon PM Tech Co,. Ltd. have been specializing in such Powder Metallurgy products as automotive, mechanical and electronic parts etc.

It is needless to say that cost and quality have been always the most important topics in manufacturing industries

a mechanism consisting of toothed wheels that engage and transmit rotary motion, usually transforming angular velocity andtorques.

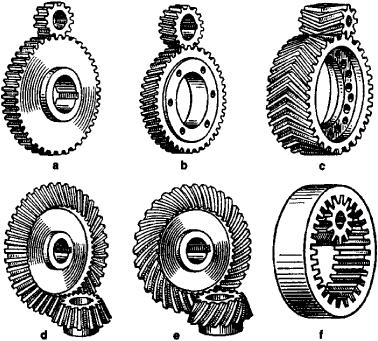

Gear drives are classified according to the relationship of the axes to the drives (Figure 1): spur gearing, with parallel

Figure 1. Gear drive with spur gears: (a) straight-cut, (b) helical, (c)herringbone, (d) bevel, (e) with spiral teeth, (f) with internal gearing

axes; bevel gearing, with intersecting axes and, in rare instances, spur-bevel and flat spur gearing; and screw drives (wormgears, hypoid gears, and screws), with overlapping axes. Rack-and-gear drive is a special type of gear drive whichtransforms rotary motion into translatory motion or vice versa. Most machines and mechanisms use external gearing—that is,gears with teeth on their outer surface. Internal gearing, in which case one gear has teeth cut into its inner surface, is usedless frequently.

Gears are made with spur teeth for operation at low and medium speeds in open drives and in transmissions, with helicalteeth for use in highly stressed drives at medium and high speeds (more than 30 percent of all spur gears), with double-helical teeth for transmitting large moments and high power in heavy machines, and with spiral teeth in all highly stressedgear drives. As a rule, gears with a constant gear ratio i =w1/w2 = z2/z1, where w1, z1 and w2, z2 are the angular velocity andnumber of teeth of the high-speed and low-speed gears, respectively, are used in machines and mechanisms. Gear driveswith variable gear ratios involve eccentric spur gears which impart a predetermined, smoothly changing speed to the drivenelement while the drive element operates at a constant speed. Such gear drives are rarely used. The gear ratio of one pair ofgears in reducers is usually as high as 7:1; in a transmission, up to 4:1; and in the drives of machine stands, up to 20:1 ormore. The circumferential speeds of high-precision spur gear drives is up to 15 m/sec; of helical gears, up to 30 m/sec; andof high-speed drives, up to 100 m/sec.

Gear drives are the most practical and widespread type of mechanical transmission. They are used to transmit power— fromnegligibly small values to tens of thousands of kilowatts-and to transmit circumferential forces of fractions of a gram to 10meganewtons (1,000 tons-force). The main advantages of gear drives are their significantly smaller dimensions, highefficiency (losses in precision-made, well-lubricated drives are 1-2 percent, and, under especially favorable conditions, 0.5percent), longer life and greater dependability, lack of slippage, and small shaft loads. The disadvantages of gear drivesinclude noisy operation and the need for precision manufacture.

Share Gear, Gear drive in Social Media