[Product Description]

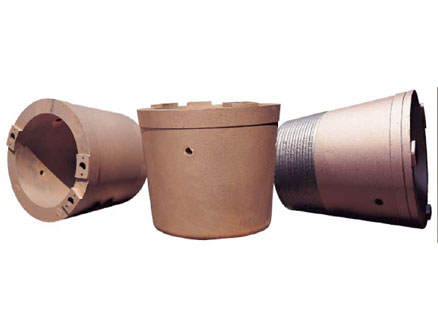

KMC developed the welded ball valves for the first time in Korea. Fully welded ball valves can be produced in sized ranging from DN 15 to DN1500(1/2 inch-60 inch) and pressire PN16 to PN420 according to international standards like AP16D, BS5351, EN488, ISO7121.

Especially, pipe forming ball valves developed by KMC uses the same material used in pipes, offering 100% adjustment to the stress of the pipe, outstanding welding performance and a complete seal that does not allow any leaks using an automatic welder.

[Product Features]:

It is not that easy to understand the care and thoughtfulness that needs to go into a gas heating valve in terms of craftsmanship or materials. But if you had ever been without heating or gas supply you would understand deeply the necessity of craftsmanship. Fully welded ball valves are one such innovation. KMC Corporation developed fully welded ball valves and pipe forming ball valves.

KMC’s fully welded ball valves are produced in sizes ranging from DN 15 to DN1500(1/2 inch-60 inch) and pressure PN16 to PN420 according to international standards like AP16D, BS5351, EN488, ISO7121. In the fully welded ball valve range the types are API 6D, ANSI Class and KMC standard valves, pre-insulated ball valves, purge assembly valves and underground ball valves.

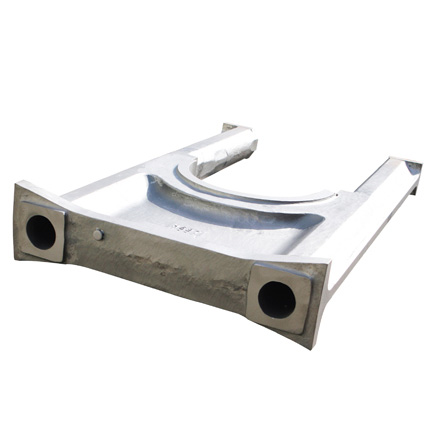

The API 6D, ANSI Class fully welded ball valves have some technical features. The features are; full and regular bore DN50 (2 inch) to DN1400 (56 inch) size ranges, pressure ratings of ANSI Class 150 ~2,500, PN 16 ~ 420, a working temperature range of -46℃(-51℉) ~ +200℃(392℉), service to oil and gas or petrochemical pipeline networks and operation available by lever, gear (vertical or horizontal), pneumatic and electrical actuator.

Standard features of API 6D, ANSI Class the include; a one-piece welded body & end-piece connection (butt weld end & flanged end), a mirror polished stainless steel ball tested spherical roundness, a pre-loaded seat springs ensure leak-tight at low pressure and reduce valve operational torque, anti blow-out stem design according to international standards, stem emergency grease fitting, stem dry bearing, metal with PTFE coating and thrust washers having self-lubricating capabilities, floating or trunnion mounted ball. The optional features of this valve class include; self-relieving seats, vertical installation and stem extension, special end-to end (face-to face) and bore size, anti-static device, seats lubricant and emergency sealant fitting, metal-to-metal seat sealing, double block and bleed, double piston effect seats, fire safe design with graphite gaskets, plastic polymer insert for seat sealing, relief valve in the body cavity and electroless nickel plating on ball and stem.

There are carefully selected materials that combine to create the API 6D, ANSI class valves. The body is constructed from carbon steel ASTM A106-B, A105, A350 LF2, A516-60, A216-WCB or equivalent. stainless steel 304 or 316 (*option upon request). The ball is stainless steel 304 or 316 grade. The seat is made from metal seat with inserted polymer seat ring, PTFE, RTFE, Viton, Nylon, Peek and more.

KMC’s pipe forming ball valves are interesting in that they are manufactured from the same material used in pipes. The pipes offer a 100% adjustment to the stress of the pipe, outstanding welding performance and a complete seal that doesn’t allow any leaks using an automated welding machine.

The company has achieved the industry standards; AP16D, ISO9001, CE, GOST, P-MARK, FFI (German certification), and CRN. KMC were in the fortunate position of being the first domestic based suppliers of fully welded ball valves to the Korean market. This did aid them to grow within Korea but their success has been based on actual quality and by answering needs as evidenced in their subsequent export success. The company’s valves are most popular in Atomic plants, gas lines in the U.S.A., desert oil fields of the Middle East and Ocean oil fields of South America as well as oil refineries of South East Asia.

The KMC Corporation was formed in 1984. KMC prides itself on delivering high quality ball valves that are safe, convenient and economically efficient. The KMC Corporation exports to more than 30 different countries around the world. The company is committed to constant research and a pioneering spirit.

Share Gas and District Heating Ball Valve(PRESSURE : 20 kg/㎠~420 kg/㎠)(Pd No. : 3003447) in Social Media