Featured Products

About Us

Global leading companies For electronic materials

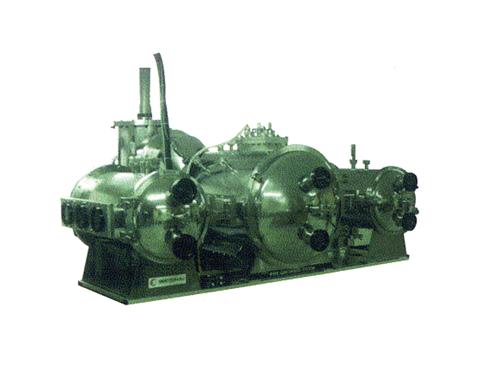

PICOMAX is engaged in the core component industry based on high technology such as vacuum equipment and insulator materials, which are being used for electronic products.

We develop electrical materials, vacuum equipment and macromolecule processing technology based on our own technical skills, and they are applied to various products.

We develop POLYIMIDE VARNISH, SILICONE LED ENCAPSULANTS, THERMAL GREASE, GEL, HARD COATING and RESIN, which are raw materials for electrical materials.

Now we are producing EPOXY RESIN, an insulator for RCC, FCCL and METAL PCB.

Furthermore, we are also developing a thermal conduction epoxy, which we apply to METAL PCB and PACKAGE PCB petal, which requires radiant heating features.

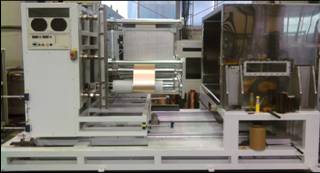

We are procuring the technology that coats metal on the surface of macromolecules based on the skills of producing and processing ROLL TO TOLL SPUTTER vacuum equipment.

We are improving the adherence with metal based on the macromolecule surface process, and this characteristic is applied to all electronic products.

Improving interior competitiveness, prime cost and quality, we exert every effort to achieve customer satisfaction, and only produce the best quality products and services.

-PICOMAX specializes in the core technology of insulation materials and Vacuum Equipment and management technology of polymer, and produces various products related to the electronics field.

-PICOMAX principal products are Polyimide varnish, Silicone resin, Epoxy resin,

Roll to Roll Sputter and FCCL process technology.

-Polyimide Varnish and Silicone which are used for LED encapsulants, Thermal Grease/Hard Coating/Gel/resin are currently included in the production lines of PICOMAX

- We also produce Epoxy Resin as insulation material used for RCC/ FCCL/ MCCL, and Metal PCB which has an excellent heat radiation capacity through the development of conductivity epoxy.

-PICOMAX has a deposition technology on the surface of polymer and a setup technology for the production lines and manufacturing of Roll to Roll sputter