Basic SummaryYou can improve productivity with the use of it, over 30~40 percent higher than the existing model 400. A screw feeder (4 lines) is used to fill up more evenly than in ways to do in the past. It is easy to clean every part of the machine individually.By raising the whole hopper, every region of meat that the hopper touches can be cleaned up. The minimum thickness of the mold plate is about 5mm and it's maximum thickness can go up to 30mm. The discharge conveyer using inverter technology can adjust the conveyer's speed according to products.

Composition of the machine

Hopper

Feed spiral

Press block

Mold plate

Hydraulic unit/Air unit(press block)

Specification

Capacity

Max. 75Step/Min

Elec. Power

20Kw

Hopper

200 Liter

Utility

Water 15A, Air 15A

Option

Lifter

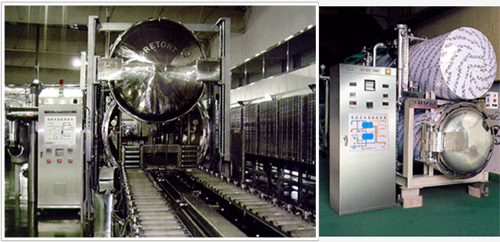

Molding Machine

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Molding Machine in Social Media