General Specification

Applicable web

: PE laminated film(Inner)

Web thickness

: Max. 200micron

Web width

: Max.1240mm

Web roll Dia.

: 500Ø

Finished bag width

: 60-500mm

Finished bag length

: 60-500mm (Time deliver function)

Sealing bar temperature' range

: 0-360degree

Unwinder shaft

: Air shaft

Production speed

: Max.160 bags/min (32m/min) : Depends on bag shape, length and thickness

Required electric power

: 18kW

Cooling water

: 3liter/min

Air comsumption

: 0.6Mpa

Dimensions

: 11505(L) * 1750(W) * 1900(H)

Weight

: 45000Kgs(N/W)

Unwinder part for main web

Web width

: Max.1240mm

Web width

: 500Ø

Web shaft with powder brake(Mistubishi brand)

: Air shaft

Lift for web roll

: By Air cylinder

Encoder

: 1set

Dancer roll

: 1set

Web infeeding roller

: 1set ( Driven by motor)

Guide roller for main web

: 1set

Web turn-bar

: 1set

L.P.C sensor

: 2sets( L.P.C control box)

Nip roller

: 1set (Driven by motor)

Slitting razor blade

: 1set

Longitudinal Sealing Unit

Longitudinal Sealing Bar

: 5sets (720mm)

Cooling Bar

: 5sets (Assembled into sealing bar)

Configuration

: Vertical disposition iron pressing, Spring pressing structure

Drive

: Main eletric machinery drives coupling rod ofeccentric mechanism to do vertical motion.

Horizontal Sealing Unit

Horizontal Sealing Unit

: 3sets (620mm)

Cooling Bar

: 1set

Configuration

: Vertical disposition iron pressing,Spring pressing structure

Drive

: Main eletric machinery drives coupling rod of eccentric mechanism to do vertical motion

Film Infeeding Unit

Configuration

: Rubber roller pressing friction type

Dirve

: 2servo drive system (Panasonic-brand)

Transmission

: Synchronous band and wheel

Control Modality

: Centralized computer control, synchronous lengthfixing and middle tension control

Middle Tension

Configuration

: Floating tension force roller structure

Control Modality

: Centralized computer control

Mechanism of Contrl

: Complementary trend of floating tension rollermovement control the middle servo step length to

Testing Form

: Electromagnetism approaches switch (NPN)

Adjustment Range of Tension Force

: 0.1-0.2mm (computer setting, automatic makeup)

Main Transmission Device

Configuration

: Crank rocker push pulling coupling rod structure

Dirve

: Transducer drives 3.7kW 3P asynchronous motor

Transmission

: Main transmission electric machinery band 1: 11 cycloid-pin gear speed reducer (SEW-Made in Germany)

Automatic Positioning Device

Testing Form

: Tracking testing of reflection photoelectrical sensor

Testing Accuracy

: 0.01-0.25mm

Integrative Positioning Accuracy

: =0.5-1mm

Photoelectrical Searching Range

: ±3mm

Rectifying Equalizing Range

: ±3mm

Positioning Rectifying Wise

: Servo tracks current equalizing, photoelectrical automatic movement rectify system

Temperature Control Setting

Testing Form

: Thermocouple test

Control Modality

: Independent control, PID adjustment, solid-state relay

Temperature Setting Range

: Normal temperature - 360degree

Warm Spot

: Middle part electric heating

Cutting Knife Part

Testing Form

: Top cutting knife+ adjustment equipment+fixed bottom cutting knife

Form

: Spring shear knife

Transmission

: Main motor driving, eccentric mechanism verticalmovement

Adjustment

: Horizontal movement (Double end)

Punching Equipment Part

Configuration

: Embowed set supports air-operated engine lead to main model impact structure

Control Modality

: Centralized computer control

Dirve

: Solid-state relay drives solenoid valueGenerally confugures two teams

Quantity of Punching Unit

: Two sets of rhombic

Exclusion From Taejin Machinery's Supply Scope

Foundation and Installation works and materials.

Remodification and reinforcement of the buildings and/or Fixtures for the installation of equipment.

Seller is free from any resposibility from Items not specified in the estimates and/or Specifications sheet.

Remarks

1year warranty after installation

Mechanical & electrical spare parts provided

Fast & kind after-sales service

Allowable fluctuation of the primary voltage is within ±5%

This specification is subject to change without prior notice for improvement

Guarantee

We guarantee for defects of the machinery and equipment, due to bad mechanical design, manufacturing errors or defects of materials and fabrication.The guarantee period is set for the period of 12 (twelve) months after the test runat buyer's factory.

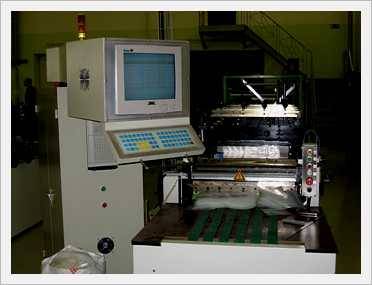

3Slide Sealing Machinery

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share 3Slide Sealing Machinery in Social Media