B. CONSISTS OF

1)

Unwinding unit

: 2sets

2)

Infeed drumroll unit

: 1set

3)

Printing unit

: 6sets

4)

Final chamber unit

: 1set

5)

Outfeed unit

: 1set

6)

Rewinding unit

: 2sets

7)

Driving unit

: 1set

8)

Electric panel unit

: 1set

9)

Standard accessories

: 1set

C. GENERAL SPECIFICATIONS

1)

Printing type

: CI FLEXO

2)

Printing color

: 6colors

3)

Applicable material

: LLDPE, LDPE, HDPE, BOPP, PAPER, CPP

4)

Working speed

: 250m/min (depends on the operator skill, material)

5)

Machine speed

: 280m/min

6)

Material width

: Max. 1150mm

7)

Guide roll

: 1200mm

8)

Printing cylinder size

: Ø127 - Ø286, 400mm - 900mm

9)

Unwinding dia.

: Ø1000

10)

Tension control for unwinder

: Automatic control system by A.C vector motor

11)

Rewinding dia.

: Ø600

12)

Tension control for rewinder

: Automatic control system by A.C vector motor

13)

Dimensions

: 3,200mm(W) x 9,350mm(L) x 4,240mm(H)

14)

Input power

: On request

15)

Machine color

: White (Basic)

16)

Drying source

: Electric heater

17)

Required air

: Pure air (Air pressure 6-7kg/cm?)

18)

Cooling water

: Under 18?, 150l/min, Pressure 2-3kg/cm?

D. DETAILED SPECIFICATIONS

1)

Unwinding unit

a)

Unwinder type

: Dual shaft type

b)

Brake

: A.C vector motor 3.7kW

c)

Tension control

: Automatic tension control system by A.C vector motor

d)

Unwinding dia.

: Max. Ø600

e)

Paper core

: 3" (inner)

f)

Shaft type

: Air expanding shaft

g)

Guide roll

: AL (Ø90 x 1200mm)

2)

Infeed drumroll unit

a)

Impress drumroll roll

: Hard chrome-plate roll (Ø1530 x 1200mm)

b)

Cooling unit

: Chiller (15Hp, air cooling)

c)

: Rubber coated roll (Ø140 x 1200mm, N.B.R HS 70-75)

d)

Structure

: Roll press type by hinge

f)

Tension control

: A.C vector motor (Inverter control system)

g)

Driving motor

: A.C vector motor (11kW)

h)

Infeed E.P.C

: End pivot guide type

3)

Printing unit

a)

Structure

: Printing cylinder roll, Pint adjustment unit, Doctor blade chamber

Anilox roll, Ink pan, Drying box

?Printing cylinder roll

-Printing cylinder size

: Ø110-Ø286, 350mm-900mm

-Material

: Steel, Horizontal shaft type

?Pint adjustment unit

-Structure

: Manual type by screw

-Material

: SS41

-Adjustment range

: ±10m/m(Horizotal), ±12.7m/m(Vertical)

?Doctor blade chamber

-Structure

: 53 x 146 x 1200mm

-Material

: AL 7075

-Knife

: 40 x 0.15 t m/m

?Anilox roll

-Structure

:Ø173 x 1200mm

-Material

: S45C, STB2, Ceramic coating

-Driving motor

: A.C worm reduction motor

?Ink pan

-Structure

: Vertical movement by spindle

-Material

: SUS 304 2t

-Ink pump

: 20Liter

?Drying box

-Drying source

-Drying capacity

: 21,000kcal/h

-Inhale blower

: 2.2kW turbo blower

-Exhale blower

: 3.7kW turbo blower

-Temperature control

: Automatic T.I.C control system

-Temperature range

: 40?-80?

-Air stream control

: Inverter control system

4)

Final chamber unit

a)

Drying source

: By electric heater

b)

Drying capacity

: 21,000kcal/h

c)

Inhale blower

: 2.2kW turbo blower

d)

Exhale blower

: 3.7kW turbo blower

e)

Temperature control

: Automatic T.I.C control system

f)

Temperature range

: 40?-80?

g)

Air stream control

: Inverter control system

h)

Guide roll

: Hard chrome-plate roll (Ø80 x 1200mm)

5)

Outfeed unit

a)

Cooling roll

: Hard chrome-plate roll (Ø214 x 1200mm)

b)

Press roll

: Rubber coated roll (Ø120 x 1200mm, N.B.R HS70-75)

c)

Structure

: Roll press type with hinge

d)

Tension control

: A.C vector motor (Inverter control system)

e)

Driving motor

: A.C vector motor (3.7kW)

f)

Outfeed E.P.C

: Center pivot guide type

g)

Guide roll

: AL (Ø88 x 1200mm)

h)

Video inspection

: Optional

6)

Rewinding unit

a)

Rewinder type

: Dual shaft type

b)

Driving motor

: A.C vector motor 3.7kW

c)

Tension control

: Automatic tension control system by A.C vector motor

d)

Rewinding dia.

: Max. Ø600

e)

Paper core

: 3" (inner)

f)

Shaft type

: Air expanding shaft

g)

Guide roll

: AL (Ø90 x 1200mm)

h)

Touch roll

: Rubber coated roll (Ø120 x 1200mm, N.B.R HS 70-75)

7)

Driving unit

a)

Unwinder

: A.C vector motor 3.7kW(2sets)

b)

Infeed and printing

: A.C vector motor 11kW (1set)

c)

Outfeed

: A.C vector motor 3.7kW (1set)

d)

Rewinder

: A.C vector motor 3.7kW (2sets)

8)

Electric panel unit

a)

Main panel

: 1set

b)

Operation panel

9)

Standard accessories

a)

Tool & Maintenance box

: 1set

b)

Static eliminater (Brush type)

: 2pcs

c)

Letter

: 1pc

d)

Guide roll

: 3pcs

e)

Rubber tube for Air shart

: 5meter

f)

Bearing for guide roll

: 5pcs

g)

Relay

: 2pcs

h)

Fuse

: 5pcs

i)

Ink pan

: 6pcs

E. PARTS DESCRIPTION

NO

PARTS

MATERIAL

MAKER

REMARK

1

Frame

SS41

INI

TAEJIN

2

Base

SS41

INI

TAEJIN

3

Driving gear

S45C

KOREA BRAND

KOREA

4

Guide roll

AL6061

KOREA BRAND

KOREA

5

Bearing (guide roll)

1203

NTN

JAPAN

6

Infeed drumroll

STB2

KOREA BRAND

KOREA

7

Infeedroll bearing

23036

FAG KBC

HANHWA

8

Infeed rubber roll

NBR

KOREA BRAND

KOREA

9

Powder brake

-

KOREA BRAND

KOREA

10

Stay bar

WHITE PIPE

TAEJIN

11

Ink pump

SUS

GRAY MILLS

US

12

Cooling unit

-

KOREA BRAND

KOREA

13

Ceramic anilox roll

STB2

KOREA BRAND

KOREA

14

Doctor blade chamber

AL7075

KOREA BRAND

TAEJIN

15

Drying box

STEEL SS41

KOREA BRAND

KOREA

16

Ink pan

SUS & SS41

KOREA BRAND

KOREA

17

Final dry chamber

STEEL SS41

KOREA BRAND

KOREA

18

End pivot guide E.P.C

FIFE

GERMAN

19

Center pivot guide E.P.C

FIFE

GERMAN

20

Rotary joint

KOREA BRAND

KOREA

21

A.C vector motor

DUTCH KOREA

NETHERLAND

22

A.C vector drive

EUROTHERMDRIVE

ENGLAND

23

Counter meter

DIGITAL

KOREA

24

Temperature control meter

DIGITAL

KOREA BRAND

KOREA

25

Electric heater

52kW

KOREA BRAND

KOREA

26

Inhale blower

2.2kW

KOREA BRAND

KOREA

27

Exhale blower

3.7kW

KOREA BRAND

KOREA

28

Air cylinder

SMC

JAPAN

29

Solenoid valve

SMC

JAPAN

30

Air parts

SMC

JAPAN

31

Driving belt

MITUBISHI

JAPAN

32

Reductor for Anilox

KOREA BRAND

KOREA

33

Driving motor for Anilox

AL

SIEMENS

GERMAN

34

Dancer roll

JAPAN BRAND

JAPAN

35

Tension indicator

ROD CELL

KOREA BRAND

KOREA

36

Machine color

OPTIONAL

37

Line speed meter

DIGITAL

OPTIONAL

38

Counter metet

DIGITAL

OPTIONAL

39

Dancer position meter

OMRON

JAPAN

40

Unwinder control

EUROTHERM DRIVE

ENGLAND

41

Infeed control

EUROTHERM DRIVE

ENGLAND

42

Outfeed control

EUROTHERM DRIVE

ENGLAND

43

Air shaft

AL

KOREA BRAND

KOREA

44

Time pulley and gear

S45C

KOREA BRAND

KOREA

45

Impress cylender

SMC

JAPAN

46

Time pulley and gear

KOREA BRAND

KOREA

47

Video inspection

MSJ

JAPAN

48

Mounter

KOREA BRAND

TAEJIN

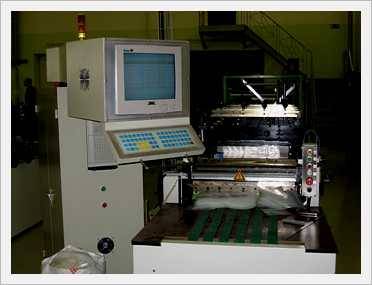

Flexo Graphic Printing Machinery

Description

Product Inquiry

Purchase Product Catalog

Payment & Shipping Conditions:

- Payment: We accept payment through Paypal Only.

- Shipping: We will ship the catalog once the payment is received. And you will be receiving the catalog with in 10 -14 busines days. Shipping might be delayed in due to international shipping conditions which is depends on the countries receiveing. In case hard copy of catalog is not available then we will ship the soft copy.

- Refund: We can refund the order before shipping process was initiated. Incase Catalog not available, we will make sure to refund the order.

- Note: This is a Catalog Produt.

Share Flexo Graphic Printing Machinery in Social Media